Free Form SCULPT 1.36kg

FREE FORM™ SCULPT is a two part sculpt-able epoxy clay

Mixing ratio (by volume): 1: 1

Hardness (Shore D): 80 D

Processing time: 80 min

Curing time: 24h

Color: grey

Feather Lite Lightweight Urethane Resin

Mixing ratio (by weight): 1: 1

Mixing ratio (by volume): 1: 1

Hardness (Shore D): 58 D

Processing time: 8.5 min

Hardening time: 2 h

Tarbender High Gloss epoxy coating 1.28kg

Tarbender High Gloss epoxy coating and encapsulant

- UV resitant

- Optically clear

Mixing ratio (by weight): 100A:41B

Mixing ratio (by volume): 2A:1B

Hardness (Shore D): 75 D

Pot life: 45 min

Cure time: 16 h

Crystal Clear 202 urethane casting resins 0.86kg

Crystal Clear 202 fully transparent polyurethane resin for castings up to 2 cm in thickness.

Mixing ratio (by weight): 100A: 90B

Hardness (Shore D): 80 D

Working time: 9 min

Curing time: 90 min

Crystal Clear 204 urethane casting resins 0.86kg

Crystal Clear 202 fully transparent polyurethane resin for castings up to max. 15 cm thick (up to 16 kg).

Mixing ratio (by weight): 100A: 90B

Hardness (Shore D): 80 D

Working time: 2 h

Curing time: 48 h

Smooth-Cast 300 polyurethane resin 0.86kg

Smooth-cast 300 castings after hardening are durable, machinable and colorable.

Mixing ratio (by volume): 1: 1

Mixing ratio (by weight): 100: 90

Hardness (Shore D): 70 D

Processing time: 3 min

Curing time: 10 min

Smooth-Cast 305 polyurethane resin

Smooth-cast 305 castings after hardening are durable, machinable and colorable.

Mixing ratio (by volume): 1: 1

Mixing ratio (by weight): 100: 90

Hardness (Shore D): 70 D

Processing time: 7 min

Curing time: 30 min

Smooth-Cast 65D polyurethane

Smooth-cast 65D castings after hardening are durable, machinable and colorable.

Mixing ratio (by volume): 1: 1

Mixing ratio (by weight): 100: 90

Hardness (Shore D): 65 D

Processing time: 2.5 min

Curing time: 15 min

Smooth-Cast 385 plastic 1.63kg

Mixing ratio (by weight): 1A:5B

Hardness (Shore D): 85 D

Processing time: 20 min

Curing time: 2 h

Color: beige

TASK 11 polyurethane resin 0.90kg

Mixing ratio (by weight): 100: 100

Hardness (Shore D): 60 D

Processing time: 20 min

Curing time: 16 h

VytaFlex 30 urethane rubbers 0.90kg

Mixing ratio: 1:1

Final hardness: 30 shA

Setting time at 23°C: 16 h

Working time: 30 min

VytaFlex 40 urethane rubbers 0.90kg

Mixing ratio: 1:1

Final hardness: 40 shA

Setting time at 23°C: 16 h

Working time: 30 min

VytaFlex 50 urethane rubbers 0.90kg

VytaFlex urethanes feature convenient 1:1 by volume mix ratios.

Hardness (Shore A): 50 A

Development time: 60 min

Curing time: 16 h

Color: off-white

VytaFlex 60 urethane rubbers 0.90kg

VytaFlex urethanes feature convenient 1:1 by volume mix ratios.

Hardness (Shore A): 60 A

Development time: 60 min

Curing time: 16 h

Color: off-white

KX Flex 60 urethane rubbers 0.88kg

Mix ratio (by volume or weight): 1:1

Hardness (Shore A): 60 A

Pot life: 2.5 min

Handling Time: 20 min

Cure time: 24 h

KX Flex 90 urethane rubbers 0.81kg

Mix ratio (by weight): 100A:120B

Hardness (Shore A): 90 A

Pot life: 2.5 min

Handling Time: 20 min

Cure time: 24 h

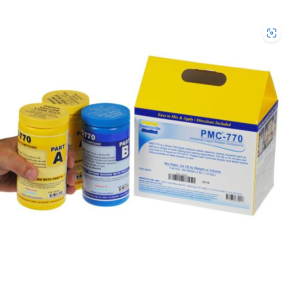

PMC-770 urethane rubbers 1.35kg

Mixing ratio: 2A:1B (by weight or volume)

Final hardness: 70 shA

Pot life: 30min.

Setting time at room temperature: 16h

Color: light amber

PMC-780 DRY urethane rubbers 1.35kg

Mixing ratio: 2A:1B (by weight or volume)

Final hardness: 80 shA

Pot life: 25min.

Setting time at room temperature: 48h

Color: light amber

PMC-790 urethane rubbers 1.35kg

Mixing ratio: 2A:1B (by weight or volume)

Final hardness: 90 shA

Pot life: 20min.

Setting time at room temperature: 48h

Color: clear amber

ECON 60 urethane rubbers 0.90kg

Mix Ratio By Volume: 1A:1B

Mix Ratio By Weight: 1A:1B

Hardness (Shore A): 60 A

Pot Life: 6 min

Curing time: 16 h

Color: clear amber

Mold Star 30 silicone 0.9kg

Mix Ratio By Volume: 1A:1B

Mix Ratio By Weight: 100A:96B

Pot Life – 45 minutes

Cure Time – 6 hours

Shore Hardness – 30 A

Color: blue

SORTA-Clear 37 silicone 0.9kg

Mix Ratio By Weight -1A:1B

Pot Life – 25 minutes

Cure Time – 4 hours

Shore Hardness – 37 A

Mold Max 29NV tin-cured silicone 1kg

Mixing ratio: 100A:10B (by weight)

Final hardness: 29 shA

Pot life: 40 min.

Setting time at room temperature: 6 h

Color: yellow

Mold Max 30 tin-cured silicone

Mixing ratio: 100A:10B (by weight)

Final hardness: 30 shA

Pot life: 45 min.

Setting time at room temperature: 24 h

Color: pink

Mold Max 60 tin-cured silicone 1.03kg

Mixing ratio: 100A:3B (by weight)

Final hardness: 60 shA

Pot life: 40 min.

Setting time at room temperature: 24 h

Color: red

Flex Foam-iT! III 1.25kg

Mix Ratio By Volume: 1A:2B

Pot Life: 35 seconds

Cure Time: 2 hours

Foam Density: 3 lb/ft³

Mixed Viscosity: 1000 cps

Expansion (approximate): 15 times

Flex Foam-iT! V 0.88kg

Mix Ratio By Volume: 1A:2B

Mix Ratio By Weight: 105A:100B

Pot Life: 50 seconds

Cure Time: 2 hours

Foam Density: 5 lb/ft³

Mixed Viscosity: 1000 cps

Expansion (approximate): 11 times

XTEND-IT 283g

XTEND-IT is a dry gas blanket designed to extend the shelf life of unused moisture sensitive polyurethane products

Skin Tite 226g

SYSTEM CONTENT:

• Skin Tite part B – 113g

• Skin Tite part A – 113g

Mixing ratio: 1A:1B (by weight)

Pot life: 3 min.

Setting time at room temperature: 5 min

Dragon Skin FX-Pro platinum silicone 0.9kg

Mixing ratio: 1A:1B (by weight)

Pot life: 12 min.

Setting time at room temperature: 40 min

Shore Hardness: 2A

Skin Tite and Thi-vex Kit – Silicone Adhesive and Special Effects

SYSTEM CONTENT:

• Skin Tite part B – 56g

• Skin Tite part A – 56g

• Thi-vex thickener – 30g

Mixing ratio: 1A:1B (by weight)

Pot life: 3 min.

Setting time at room temperature: 5 min

Ultimate Blood Kit 0.398 kg

SYSTEM CONTENT:

• Ultimate Blood Base – 254.5 gms

• Ultimate Blood Thixo – 25 gms

• Ultimate Blood Diluent – 35 gms

• Ultimate Blood red color – 28 gms

• Ultimate Blood Yellow Tint 28 gms

• Ultimate Blood Blue Tint – 28 gms

SIL-Poxy Silicone Adhesive

- Can be used repairing torn silicone rubber molds.

- Will work with tin- or platinum-cure silicones

- Provides a strong, flexible bond

THI-VEX Silicone Thickener

THI-VEX is made especially for thickening Smooth-On silicones for vertical surface application (making brush-on molds).

UVO Colorent WHITE 167g

For maximum UV resistance, UVO™ pigment should be used with a UV-resistant material such as Crystal Clear plastics or Clear Flex™ rubbers. Recommended loading range is .01% to 3% of total system weight.

UVO Colorent BLACK 86g

For maximum UV resistance, UVO™ pigment should be used with a UV-resistant material such as Crystal Clear plastics or Clear Flex™ rubbers. Recommended loading range is .01% to 3% of total system weight.

SO-Strong BLACK pigment 56g

Pigment for tinting urethane rubbers, plastics, foams and epoxy systems.

Silc Pig FLESH pigments 113g

SILG PIG silicone color pigments are used for coloring Smooth-On‘s silicone rubber compounds including MOLD MAX™ translucent ‘T‘ Series, DRAGON SKIN™ and ECOFLEX™ rubbers. SILG PIG™ pigments also are also used to create mind blowing skin effects with systems such as PSYCHO PAINT and SKIN TITE. Pigments are concentrated, recommended loading range is 0.001% to 3% … Read More