Description

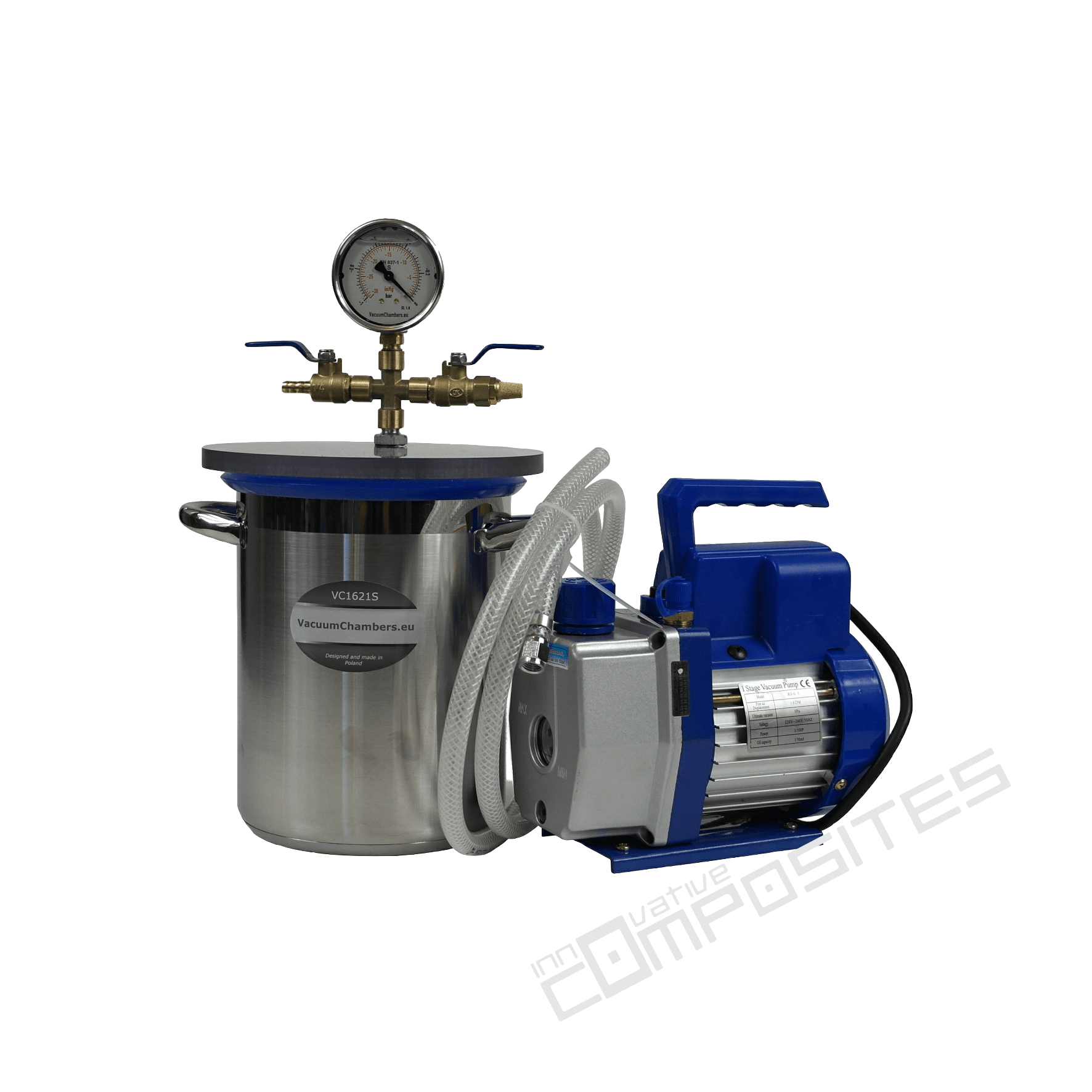

Vacuum set is used in degassing process of molding products such as silicone, resin (polyurethane, polyester, epoxy), gypsum, wax.

The chamber’s body is made of stainless steel , its capacity is 4.2l and internal dimensions are: diameter 16cm to 21cm in height. Lid is made of thick polycarbonate. The chamber is provided with a silicone seal. The applied seal is reliable and has a low susceptibility to mechanical deformation. Excellent transparency of the lid allows you to observe degassing process. Two ball valves allow you to freely control the course of the degassing process and mounted glycerin vacuum gauge indicates current vacuum in the chamber. The chamber is equipped with a intake air filter, which effectively makes it impossible to get any dirt to degassed material. The chamber is attached to a pump with a pneumatic fitting, which is fitted in reinforced hose with an internal diameter of 8 mm and a length of 1.5 m. The product is made from materials of the highest quality and branded sealant to the threads.

The vacuum pump VP1RS-0.5 is a single stage, oil pump with free air displacement of 51l/min (1.8CFM) and ultimate vacuum 5Pa (37microns).

New series of vacuum pumps is characterized by high efficiency, very high vacuum value and quiet working. RS vacuum pumps represent high quality for a reasonable price and are covered by a one year warranty.

All RS series pumps are equipped with oil mist filter and a one-way mechanical valve. This valve prevents the backflow of oil from pump into the chamber.

Pay in three equal instalments 3 x

Pay in three equal instalments 3 x

Reviews

There are no reviews yet.